Aerothan is a special thermoplastic polyurethane which Schwalbe has developed in cooperation with BASF. It serves as base material for high end bicycle tubes, Aerothan tubes, which are made in Germany using a patented welding process.

Schwalbe presents the new generation of its Aerothan tubes. The extremely light and robust tubes are now equipped with an aluminum shaft and an external thread (previously: plastic). This not only provides additional stability and improved handling, but also offers various compatibility advantages.

At the same time, the Aerothan tube impresses with its key performance advantages: Minimal weight, very low rolling resistance and a high level of robustness. It has been awarded the test winner in all six specialist magazine tests in which it has taken part - most recently in Bike (01/2025) and Mountainbike (9/2024). As before, the new Aerothan inner tubes are produced at Schwalbe's headquarters in Reichshof, North Rhine-Westphalia, and are now available in stores. The selection ranges from small to large: Schwalbe offers a total of 39 different articles.

Development in our Schwalbe Lab

In the development of Aerothan Tubes Schwalbe went in a new direction from the beginning. The result is a high-end alternative to conventional bicycle tubes. When it comes to high-end bicycle tubes, this becomes an exciting challenge. The engineers have to reconcile the apparent opposites of lowest weight and highest puncture resistance. A case for the Schwalbe Lab, where material compositions and design principles are redeveloped to create unprecedented products. And this is how the Aerothan Tube has been improved even further.

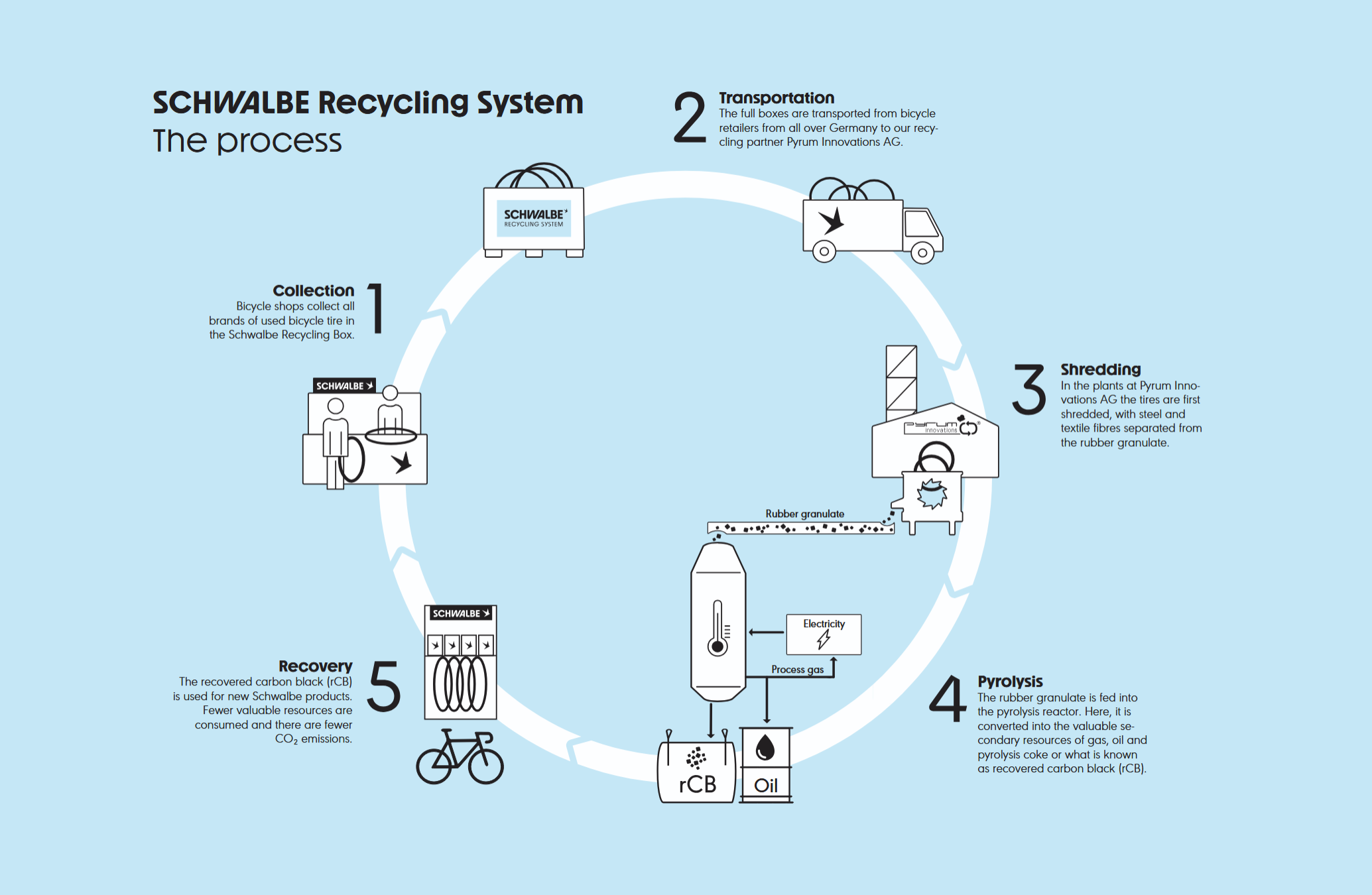

Aerothan also sets a new milestone from an environmental perspective

The TPU material for the inner tubes comes from BASF. For chemical recycling (ChemCycling® ), the chemical company uses the pyrolysis oil obtained from Schwalbe's own tire recycling process. This is fed into composite production at the beginning of the value chain and allocated to the TPU via the mass balance. This saves fossil resources (crude oil) and the Aerothan inner tube contributes to the circular economy

Aerothan vs. Butyl: The difference

.jpg)

PLUNGER TEST

In the so-called plunger test, a spike with a spherical tip (1 mm diameter) is inserted into the tube under increasing pressure until it can no longer withstand the pressure.

The Aerothan Tube is superior to all other tubes in the test in terms of force application at 47 N and on a par with a latex tube in terms of stretch behavior at 18 mm.

.jpg)

SNAKE BITE TEST (ROAD)

In the snake bite test, a drop axe is dropped onto the tire from an increasing height until the tube loses air due to a snake bite.

The Aerothan tube can withstand greater drop heights than latex or plastic tubes and therefore offers significantly greater protection against punctures.

.jpg)

SNAKE BITE TEST (MTB)

In the mountain bike-specific snake bite test, a rounded drop axe is dropped onto the tire to simulate impacts from roots and stones. The drop height is increased until the tube loses air due to a snake bite.

The Aerothan Tube is on a par with tubeless systems and offers significantly greater protection against punctures than the X-Light butyl tube in the MTB-specific test procedure

.jpg)

WEIGHT

The weight is based on an average value for which ten tubes were weighed per model.

The Aerothan Tube saves over 50 g in weight compared to the Schwalbe Extralight and offers drastically better puncture protection

.jpg)

ROLLING RESISTANCE

In the rolling resistance test, the tire rolls at a speed of 40 km/h. The power required to maintain this speed is measured.

The rolling resistance with Aerothan Tube is about the same as that of the latex tube. However, with significantly less weight

.jpg)

HEAT RESISTANCE DYNAMIC

In the heat resistance test, a starting temperature of 30°C is selected and tested at 78 km/h with 30% braking force. In addition, it is determined how many emergency braking applications the tube can withstand.

In the dynamic test, the Aerothan Tube emerges as the winner and is the only tube to withstand 7 emergency braking maneuvers in a row. All Aerothan Tubes are approved for use with rim brakes.

Good to know: Aerothan Tubes do not burst suddenly. In the worst-case scenario, air is lost slowly and the bike generally remains controllable

Aerothan-Plus tubes with increased wall thickness

Same low rolling resistance as the standard Aerothan tube

80% more puncture resistance compared to the standard Aerothan tube

20% more puncture protection compared to the standard Aerothan tube

. tube

40% higher weight compared to the standard Aerothan tube

In addition, Schwalbe's new Aerothan has several compatibility advantages thanks to the new external thread:

Compatible with all pumps

Compatible with the Schwalbe Airmax

Compatible with the Bosch Speed Sensor

Compatible with the Schwalbe ClikValve

The Aerothan Tube range

The new Aerothan tube is available in different sizes and with different valves to ensure that you have the ideal tube for your application. The Aerothan tubes are also available in the “Plus” version with increased thickness and even higher puncture protection.

FAQ

GENERAL

Aerothan tubes are extremely light, yet highly puncture resistant. The low rolling resistance offers an extremely dynamic riding experience. Aerothan retains its shape and ensures stable riding characteristics on all bicycles, even at low air pressures. At the same time, its dimensional stability makes it easy to install because the tube does not slide around and cannot get pinched.

Schwalbe is the expert for tubeless tires. However, some cyclists prefer using a tube despite tubeless as the state-of-the-art option. Additionally, certain wheel types are not suitable for tubeless. Therefore, we have developed Aerothan tubes – the high-end alternative to conventional bicycle tubes. Many of its technical advantages achieve the same high standards that tubeless systems do.

Aerothan tubes are available for all common tire sizes for: BMX, Cargo, Urban, Tour, Gravel, Road and MTB. You can find an overview with all sizes here.

Aerothan tubes are available in the categories Road, Allround and MTB, where Aerothan has extremely diverse areas of application due to its particular material characteristics. You can find an overview with all sizes here.

Aerothan is a flexible material and is subject to limited tolerances (as opposed to solids such as metal). Despite highly elaborate manufacturing and control procedures, deviations in weight of +/- 5% may occur.

Like all Schwalbe tubes, Aerothan tubes are 100% recyclable. As opposed to conventional butyl tubes, Aerothan tubes are completely made of a thermoplastic polyurethane – including the valve. This makes the recycling process even more straightforward. We are currently working with our partners on the details of the recycling process and the return of used Aerothan tubes.

Aerothan is extremely temperature stable. The material can withstand both high temperatures of up to +70°C and low temperatures of down to -50°C without any problems.

INSTALLATION & SERVICING

The transparent Aerothan material changes colour when in contact with the compounds of the tread. This is due to diffusion of volatile substances which are released as a result of the vulcanization process. This occurs especially with new, unused tires. The change in colour has no impact on performance or durability of the tubes.

If a sealant is no longer able to seal the tire while you are on the road, you can of course use the Aerothan Tube as a first aid measure, even without completely removing the sealant from the tire. Afterwards, the tube should be cleaned as quickly and thoroughly as possible with water and a cloth or cleaning alcohol. Under no circumstances should chemicals be used to clean the tube. The tire should be replaced depending on the size of the defect.

An Aerothan tube may be inflated carefully outside the tire until it has no more folds and is round in shape (equivalent to max. 0.3 bar).

Yes, however, a CO2 cartridge should only be used once the tube has been fully installed. Outside the tire, Aerothan tubes may only be inflated carefully until they reach a round shape and are free of folds (equivalent to max. 0.3 bar); CO2 cartridges are not intended for this purpose.

Yes, however, an Aerothan tube may only be reinstalled into a tire of the same or of greater width.

Sealing liquid does not achieve any sealing effect with Aerothan tubes because the surface tension of thermoplastic polyurethane (TPU) is very high. Using latex based sealing liquid for tubes made of TPU is not recommended due to the chemical composition. For optimal performance, Aerothan tubes should only be used in tires without sealing liquid. Long-term use with sealing liquid is not recommended.

Repair sprays do not achieve any sealing effect with Aerothan tubes because the surface tension of thermoplastic polyurethane (TPU) is very high. Using repair spray for tubes made of TPU is not recommended due to the chemical composition. For optimal performance, Aerothan tubes should only be used without repair spray. Long-term use with repair spray is not recommended.

If a sealant is no longer able to seal the tire while you are on the road, you can of course use the Aerothan Tube as a first aid measure, even without completely removing the sealant from the tire. Afterwards, the tube should be cleaned as quickly and thoroughly as possible with water and a cloth or cleaning alcohol. Under no circumstances should chemicals be used to clean the tube. The tire should be replaced depending on the size of the defect.

Talcum is not harmful to the AEROTHAN Tube. However, it is not necessary to use it, as the AEROTHAN Tube is provided with a special lubricant during production. In addition, the friction between the TPU material of the tube and the rubber carcass of the tire is extremely low.

All Aerothan tubes are approved for rim brakes. Aerothan tubes are extremely resistant to heat and can sustain high thermal stress (for example during emergency braking). Also, in case of a defect, air does not suddenly escape, which is why riding stability remains unaffected.

All Aerothan Tubes are suitable for use with carbon rims. Here, too, the heat resistance of Aerothan material is an advantage over latex and butyl.

Tyre pressure sensors can be mounted if they are screw-in systems. These are then screwed onto the visible external thread of the valve core. Please check compatibility with the respective supplier.

"Rim tape, when used correctly, always provides additional protection against defects. The Aerothan Tube is generally compatible with all common rim tapes. It is best used with Schwalbe Tubeless Rim Tape (https://www.schwalbe.com/en/TUBELESS-RIM-TAPE-887029). Always make sure that the width of the rim tape matches that of the rim. If the rim tape does not lie neatly from flank to flank in the rim bed, it can come into contact with the tube. See also: https://www.schwalbe.com/en/technology-faq/rim-tape/

Mini pumps with screw-on pump heads (e.g. from Lezyne) can be used. To do this, the valve core of the Aerothan Tubes must be firmly seated in the valve stem (see above reference thread locking compound). The pump head should be screwed onto and off the valve core with as little tension as possible. Ideally, the valve stem should be held in place while screwing and unscrewing the pump head, so that only the thread of the pump head is moved.

VALVE

The Aerothan tube is available in various versions. With the exception of the 100mm version, which is still made of plastic, all SV and SCV Clikvalve versions come with an aluminum shaft. The lengths are available in 40, 60 and 80mm. All aluminum shaft versions have an external thread. There is also an AV version made of reinforced plastic with an external thread, which is ideal for everyday use.

"The valve core of the Aerothan Tube is screwed in and can be replaced if necessary. This also makes the valve stem suitable for extensions.

The SV shafts are compatible with all standard Sclaverand inserts. Conversion to the SCV ClikValve is also possible without any problems.

An AV valve hole has a diameter of approx. 8.5 mm. The SV valve of the Aerothan Tube has a diameter of approx. 6.1 mm. This difference can lead to noise while riding and puts above-average strain on the material. In this case, a reducing sleeve should be used, which is pushed over the valve stem of the Aerothan Tube and held in the valve hole by the valve. Reducing sleeves or valve hole adapters are not available from Schwalbe.

An AV adapter can be used. For a secure fit, it must be screwed approx. 3-4 turns onto the external thread of the valve insert.

The valve base is conically shaped towards the tube. It serves as a support for the valve stem, thus counteracting strong mechanical effects, such as shear forces. During assembly, the cone can rest on the rim well and retracts slightly into the valve hole as the air pressure increases. This ensures that the valve stem is held securely in the valve hole. The valve base is made of the same material as the tube, so that the tube and valve base expand evenly.

TIRE PRESSURE

"Thanks to their enormous shape stability, Aerothan Tubes can be used at significantly lower air pressures than conventional bicycle tubes. The recommendations for tubeless systems can be used as a guide for the correct air pressure. It should be noted that the minimum pressure engraved on Schwalbe tires is for use with butyl tubes. When using Aerothan Tubes, the values may be lower. The Schwalbe MTB Pressure Prof can be used to quickly and easily calculate the optimum air pressure in the tire online:"

At the maximum pressure for Aerothan Tubes, the pressure range indicated on the tire side or rim should be observed. If the specified tire pressure of the rim is lower than that of the tire, the maximum pressure of the rim must be observed. If in doubt, contact the manufacturer.

Aerothan tubes are on a par with butyl tubes in terms of how well they retain air. Frequent re-inflation, as is necessary with latex tubes, for example, is therefore not necessary. For optimal performance, it is recommended that the air pressure be checked regularly.

The Aerothan Tube can be left in the tire without concern. It is recommended that the tire pressure be slightly reduced by one to two bar below the maximum permissible air pressure of the tire or rim (whichever is the lower). Information on tire pressure can be found on the side walls of bicycle tires. Find out more at: https://www.schwalbe.com/technik-faq/spezielles/https://www.schwalbetires.com/technology-faq/special/