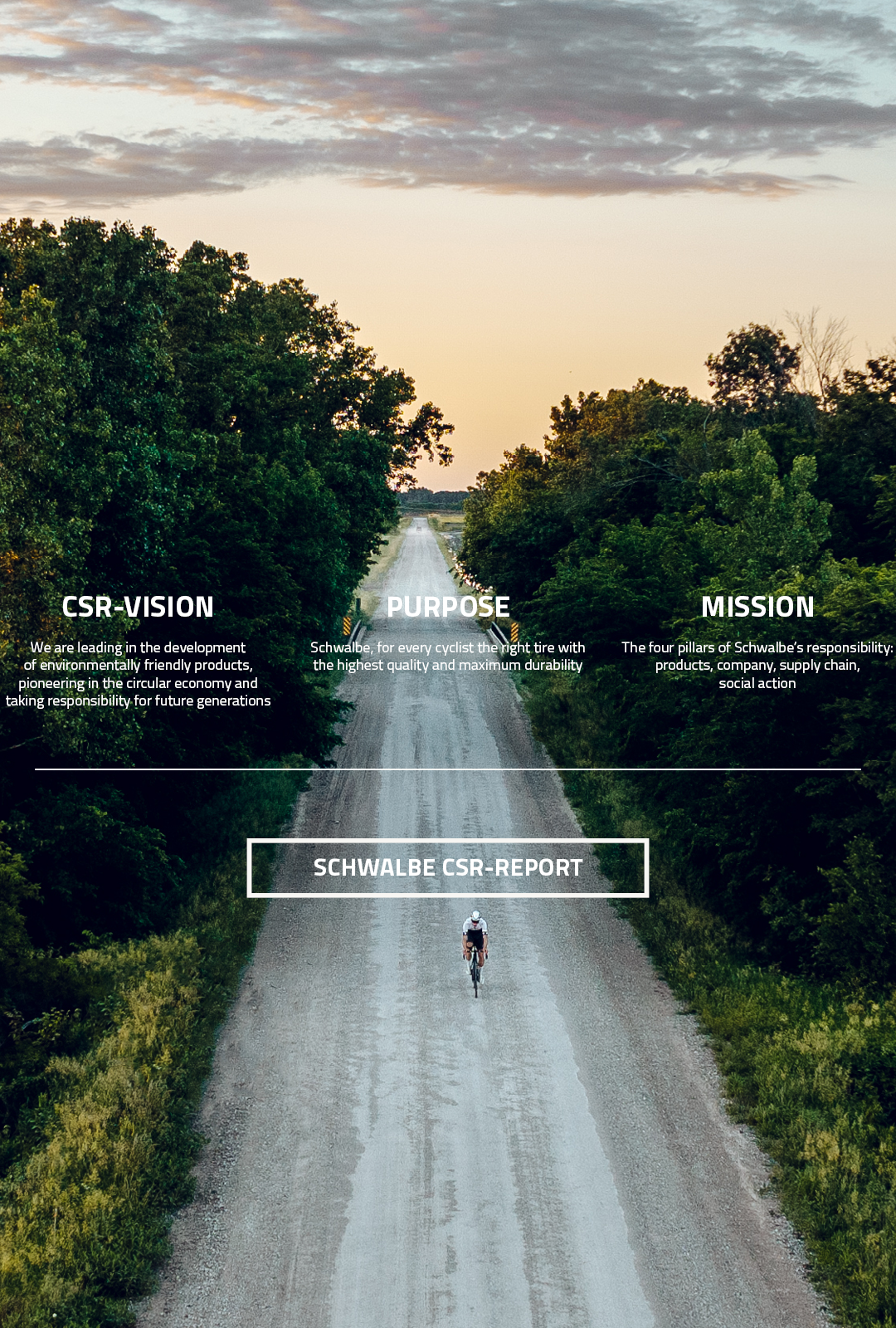

RESPONSIBILITY

FOR THE NEXT GENERATIONS

With our first CSR report we are not only setting goals, but we are also officially establishing our social and environmental responsibility throughout the company. It not only provides information for our employees and the industry as a whole, but also serves as an inspiration to further develop their responsibility – for the people and for our planet.

The CSR Report is based on the Sustainability Reporting Standards of the Global Reporting Initiative (GRI Standards). These internationally recognized guidelines enable standardization and comparability of all sustainability topics between different companies, even outside the bicycle industry.

THE FOUR PILLARS OF THE SCHWALBE RESPONSIBILITY

– Chancenwerk

– Regional support (VfL Gummersbach, TTC Bergneustadt)

FUTURE UNDERTAKINGS – OUR CSR MARATHON

As one of the first companies in the bicycle industry, we have set ambitious CSR goals in our four pillars of responsibility.

13 million recycled inner tubes

2024

CSR: Corporate Social Responsibility means responsible business management, which integrates ecological and social aspects.

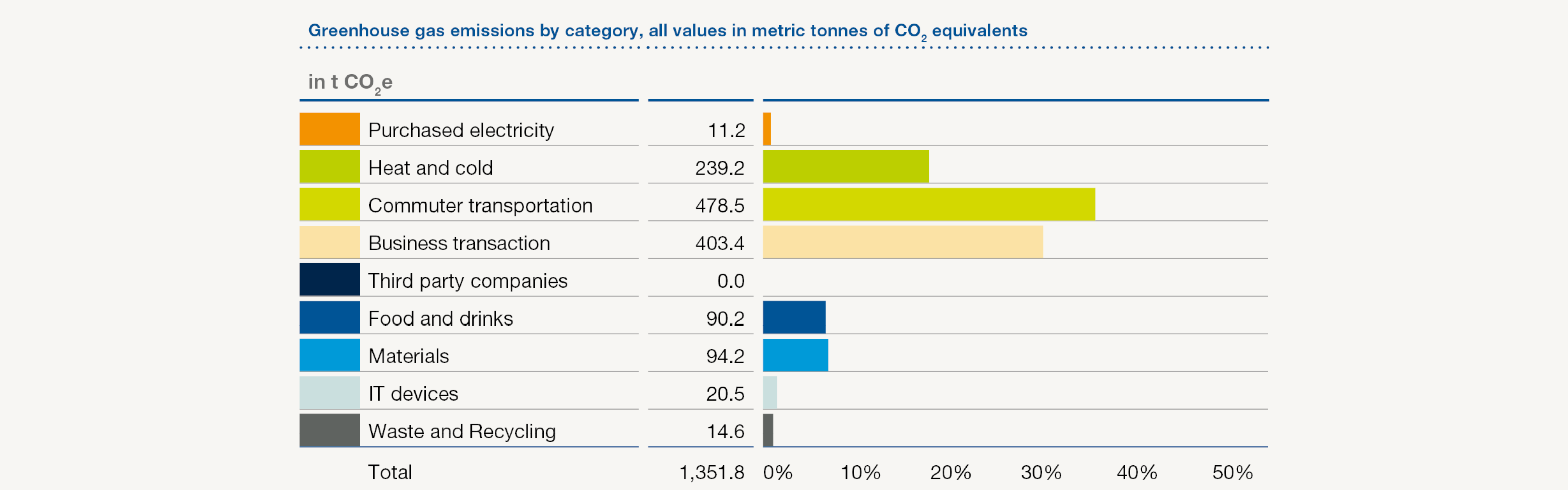

Our inspiration is the CRADLE TO CRADLE design. This is all about thinking in cycles. Products and processes are conceptualized in such a way that all materials can be recycled after their use. This is already taken into account during the design and manufacturing process.