WHAT IS A CLINCHER TIRE?

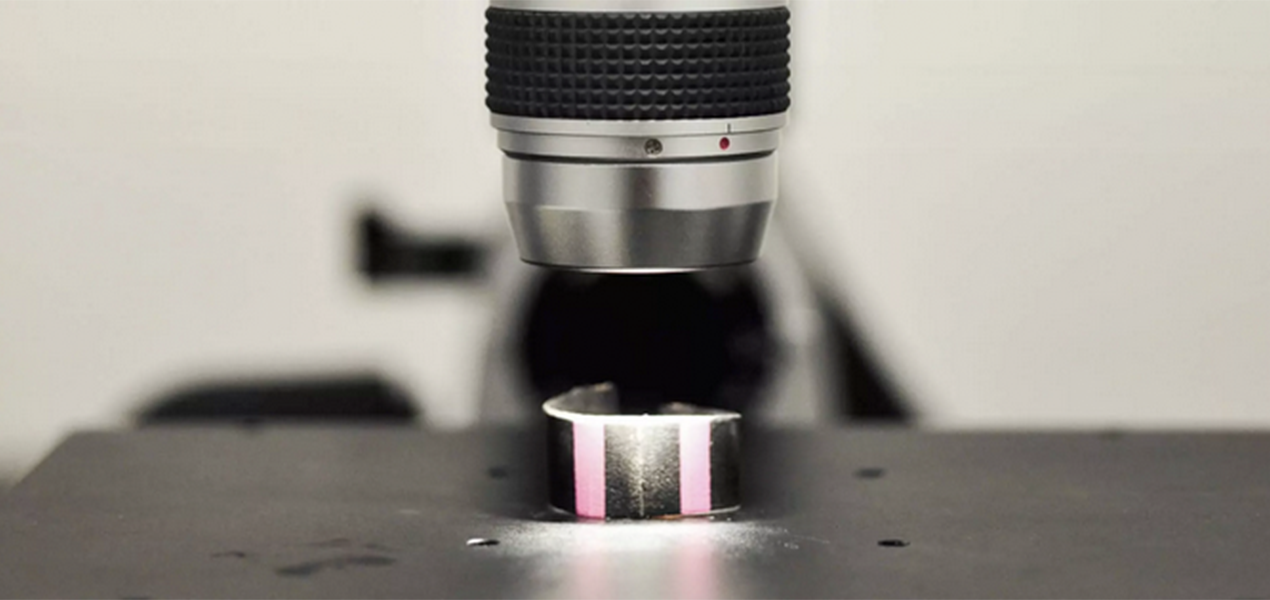

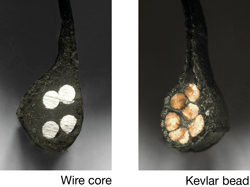

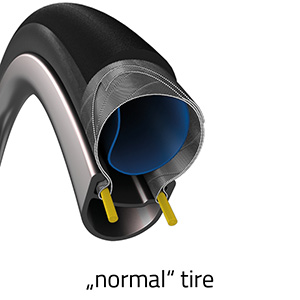

Today clincher tires are standard for bicycles. See Tire Construction. The wire bundle in the tire bead prevents the tire from expanding with the pressure and thus from jumping off the rim. Clincher is the international designation for this type of tire.

WHAT IS A FOLDING TIRE?

A folding tire is a special version of the clincher tire. The wire bundle is replaced by a bundle of Kevlar strands. This enables the tire to be folded up and depending on the tire size, makes it approx. 50-90 g lighter.

WHAT IS A TUBULAR?

In a tubular tire, also referred to as Tubular or Collé, the tube is sewn directly into the tire. The tire is then glued onto a special rim.

Many professional road racers still swear by them, claiming that they provide a better “feeling” and that the tires have more “life”, i.e. better comfort and smoother cornering. At least with regard to rolling resistance, this assumption is now outdated. Modern folding tires have certainly caught up with tubular tires in terms of rolling resistance and roll even easier.

However, a clear advantage of tubular tires lies in their run-flat capability. Even with a flat, the tire stays on the rim. The rider can safely stop without losing control of the bicycle, or even slowly ride on until the team car arrives.

WHAT IS A TUBELESS TIRE?

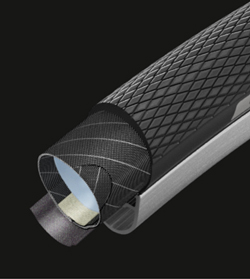

Tubeless tires provide clear advantages in speed, comfort, grip and puncture protection. They avoid unnecessary friction between tires and tubes, which reduces the rolling resistance even more than with super light competition tires. Tubeless tires can be used with a lower inflation pressure without compromising performance. That brings clear advantages in comfort as well as clearly more control in critical situations and on trails with poor surfaces. At the same time, tubeless systems provide a high puncture protection. The danger of blowouts is clearly reduced. A sudden loss of air pressure caused by a burst tube or a valve tear off is excluded. What is more, tubeless systems function perfectly together with puncture protection liquids. Punctures are re-sealed within milliseconds.

WHAT DOES TUBELESS READY OR TUBELESS EASY MEAN?

Tubeless Ready tires are not tubeless tires. By using sealing liquid in a special process they can, however, be converted into tubeless tires. Schwalbe Tubeless Ready tires have a coated tire bead which has a special shape. This provides a good sealing with the rim and a perfect fit..

WHAT IS THE DIFFERENCE COMPARED TO NORMAL TIRES?

The conversion from normal tires into tubeless tires is something road racers have been practicing for quite a long time. With the Schwalbe Tubeless Ready and Tubeless Easy tires this conversion is significantly easier. The special tire bead provides an immediate sealing with the rim and a perfect fit. In the case of normal tires the sealing in the area of the rim is very problematic, as it often works only by using a compressor and takes a lot of patience. Often, it takes several days until this transition area is actually sealed. There is also an increased risk of the tire coming off, as the tire cores are not designed for being used as tubeless tires.

Due to the necessary high inflation pressure for a road bike, it is absolutely impossible to convert classic tires to tubeless tires. A normal tire bead will not withstand these forces and the tire will almost certainly come off. Be sure to only use tires which are designed for tubeless fitting!